![[SoundStage!]](../sslogo3.gif) The Traveler The TravelerBack Issue Article |

February 2008 Giro del Veneto: Pathos Pathos Acoustics has, for the past dozen years or so, created its own distinctive place in the audio market, combining stunning post-modern design with innovative electronics to produce audio equipment of high refinement in both sight and sound. Each item in its line exudes stylishness and Italian sophistication; as with premium cars and designer sunglasses, you remember the looks as well as the performance. My first glimpse of a Pathos product was of the Classic One Mk III integrated amplifier ($3000). It had the topside lines of a California cruiser designed for weekend getaways to Baja. My latest glimpse was of the new InPower monoblocks ($7500 each) at CES 2007 -- massive rectilinear silver blocks about the size of elegant, low-slung lamp tables, illumined from the chic cutaway vee-chambers of its glowing input tubes. The Pathos catalog consists of ten eye-popping products -- two CD players, a preamp, and seven amplifiers -- each with its own snazzy look and name.

I visited the Pathos factory in Vicenza, Italy -- a city near Venice, famous in its own right for architecture, goldsmithing, and jewelry manufacturing. I was squired around by none other than the company's director of research and development and chief engineer, Gianni Borinato. He'd handed me his card at CES and I'd kept it, oddly enough, amidst papers with my passport, but I had no idea then I'd be visiting him on his home ground.

On the way to Pathos, a half-hour drive from my downtown hotel to the outskirts of town, Gianni filled me in on the history of his company. He said he'd gotten together with two friends of his -- Gaetano Zanini and Paul Adriolo -- back in 1994 when he came up with a new circuit design for an amplifier. He called this INPOL technology – "Insequitore a Pompa Lineare" in Italian, "Linear Pump Tracking" in English. "We three were friends around music," Gianni said, turning into the Pathos lot. Gianni (guitar) and Paolo (keyboards) played in a band together, and Gaetano ran a hi-fi shop they all hung out in. "It was synergistic," Gianni said. Together, they came up with the prototype for the Twin Towers, a 35Wpc hybrid integrated amplifier, currently $7500 in its Anniversary version -- the first Pathos amplifier -- and thereby made a spectacular start in the business of hi-fi manufacturing.

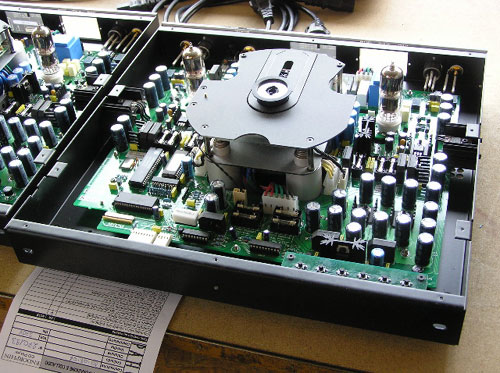

"With the Twin Towers amplifier, we established the philosophy that each new product should feature its own electronic and design innovations," Gianni said. "So both the operation and the looks of the component are unique." Gianni explained that it was not the goal at Pathos to make electronics at all similar to or on par with equipment out there manufactured by others. It is not only that every product must contain technological innovation, but that it contains innovation that improves performance. "Of the Pathos beauty -- your ears must hear what your eyes can see," Gianni said, speaking like a Zen master. The Pathos factory itself is a fairly large building, as far as hi-fi manufacturers go, in the industrial-park area around Vicenza. It is three floors and 2000 square meters, housing all aspects of manufacturing -- shipping and receiving (parts from elsewhere), metal and wood finishing, assembly, testing, marketing, and some design. There are ten workers plus the three owners and two administrative staff. Gianni whipped me along past dozens of pallets and tables loaded with amplifiers and CD players partially assembled. He explained that while Pathos builds most of its own essential parts here, things like transformers and baseboards are outsourced. "But we do all the circuit boards, assembling, soldering, and electronic calibrations in-house," he said.

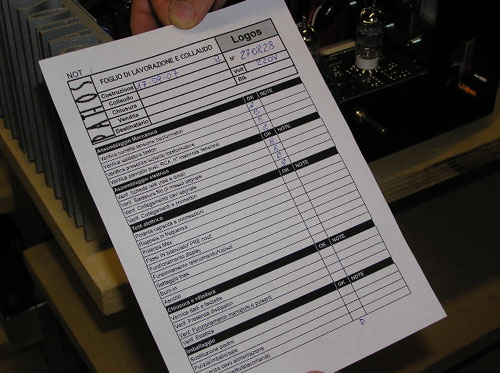

Any Pathos unit goes through two assembly stages -- electronic and chassis -- then two testing procedures -- electronic and acoustic. Finally, there is finishing, closing, and the packaging of the unit. Each step is checked along the way, and Gianni showed me an inspection list that is used for each unit. A worker verifies not only that each step has been done, but that he or she is satisfied that it is done well. Every Pathos unit is vouched for at least 25 separate times.

As with other audio Italian factories I'd visited, there seemed to be units in various stages of completion throughout the Pathos factory -- no Detroit-like assembly line. "That is true," Gianni said. "We do not hurry. We do not put together our components in the mass-production fashion." The Inpol 2 ($11,000), for example, takes about 15 hours of in-house manufacture -- nearly two complete days. Then it's tested and burned in for another eight hours before it's packaged and readied for shipping -- about three days total. He said they valued a kind of slowness at Pathos, that each worker performs at his own pace and is satisfied with each step of manufacture. This meant that components go through several segmented steps of assembly and testing, that nowhere would I see a piece of Pathos electronics move down a conveyor belt, morphing from screws and bolts to a full-blown music machine. The process reminded me of how a play was rehearsed -- in smaller scenes, perfected separately rather than run together at first. A certain fineness is imparted this way, the work of artisanship. Typically, they have orders projected ahead about six months and have all the requests they can handle, shipping about 150 units every month.

Downstairs, Gianni and I ran into Gaetano Zanini, the CEO, who, dressed in jeans and a T-shirt, was overseeing the finishing of some Pathos heatsinks, wood inserts, and faceplates. Gaetano showed me how they bought the metal for the famous Pathos fins, spelling out the Pathos name, in bars of six meters. These are then cut, polished with a sand-gun, and painted with a special aluminum-and-resin paint to resist scratching. There were two CNC routers and a massive metal-polishing machine spaced around the shop floor, pallets of faceplates and CD clamps, and a circular stack of red-stained wood lying about. Gianni explained that the wood inserts for the Pathos faceplates take three separate series of painting and sanding before they are mounted. The aluminum pieces take two. "I want you to know how we do things the slow way here," Gianni said as we left for lunch. "Do you see anybody who is in a hurry? Anyone watching over them, applying the pressure to go fast? -- No!" he said emphatically. "Our way is to make each product good -- like the music you hear." Later that day, over lunch at a downtown Vicenza ristorante, we ate slices of tuna, lightly seared, and shellfish, raw on beds of ice -- all of it caught near Venice. Gianni told me of his loves in music -- Keith Richards, the '60s country-rock group Poco, and most of all the Eagles. He said that he believed audio and hi-fi should reflect lifestyle, that quality of parts was like quality of ingredients in cooking, that design and sound were like presentation and flavor in food. "And you have to take the time to admire what you are doing," he said. Audio engineering was not a job to him nor merely a business to Pathos. "It is a pleasure," he said. ...Garrett Hongo |

|

![[SoundStage!]](../sslogo3.gif) All Contents All ContentsCopyright © 2008 SoundStage! All Rights Reserved |