November 2008

Factory Tour: A Touch of

Classé

by Colin Smith

We audio reviewers are a fortunate bunch. Not

only do we get to play with all manner of audio gear, but we also get to meet quite a lot

of people in the audio business. You can learn a lot about a company by speaking with its

owners, engineers and management. But if you want to get the full perspective, you’ve

got to visit these folks at their factory, the place where creative inspiration becomes a

tangible product. We undertake such visits whenever possible, so when Soundstage! Network

publisher Doug Schneider and I were recently invited to tour the Classé Audio

facilities just outside Montreal, Canada, we didn’t hesitate to accept.

Classé Audio's main entrance.

Like the universe, Classé Audio began with a big

bang. As vice president Dave Nauber tells the story, back in 1980, company co-founder (and

current chairman) Mike Viglas was hosting a party at his Montreal home when suddenly one

of his amp’s output tubes failed in spectacular fashion. "Mike gets a kick out

of describing how people were picking little bits of vacuum tube out of their hair,"

says Dave. Sure, it seems funny now. But back then, the incident led Mike to

conclude that he needed a solid-state amp, if only to avoid peppering more guests with

tube shrapnel.

After fruitlessly auditioning every solid-state

design that local dealers could lay hands on, Mike was ready to give up when someone

suggested that he get in touch with a local amp designer, David Reich. This fellow was

rumored to be working on a solid-state design that would leave its contemporaries in the

dust. That must have been the case, because Mike not only bought an amp, he and Reich

decided to form Classé Audio. The new venture was named for Reich’s favored

amplifier topology, class A, and not, as you might expect from a Canadian company,

"Class, eh!"

With David’s designs and Mike’s

marketing savvy, Classé was built into a globally successful enterprise with a reputation

for designing great-sounding components. But, as often happens in life, over time the

founders began to have diverging views on the company’s direction. It was decided

that some major changes were in order, so, as the new millennium dawned, Mike Viglas went

looking for a new strategic partner.

He found one in 2001, when Classé became the

high-end electronics division of the Bowers & Wilkins Group, better known as B&W

Loudspeakers. Obviously B&W’s management liked what they saw at Classé because

it was decided that the Canadian division would remain a separate entity. However, in a

move which must have been very reassuring to Classé’s employees, the company was

also given responsibility for designing and assembling all the electronics used in

B&W’s products. For the present, this means that Classé builds subwoofer amps

and the electronics used in the B&W Zeppelin iPod dock. For the future, well, we

promised we wouldn’t tell.

With the infusion of B&W resources also came

Dave Nauber, who was educated as an electrical engineer and had been involved in the

management of the Madrigal group of companies. Dave’s first order of business was to

rally the Classé troops around the audacious goal of completely reinventing the company,

a task that was given the code name Project Delta. Dave told us that in engineering, the

term "delta" is used to denote the difference between one thing and another, and

so it was the perfect name for a new series of products that would mark the transition

from the old Classé to the new.

The Classé boardroom still shows signs of

Project Delta’s early days. No, there aren’t any holes in the walls! However,

there are a number of large posters, dated 2002, which show a variety of chassis studies

developed by an industrial-design firm in the UK. It must have been difficult to choose

the design that ultimately came to be the new face of Classé, because all of the studies

we saw were excellent. Incidentally, I’m not sure if Classé is aware of this, but

when I looked up the factory’s address on Google Maps, I couldn’t help but

notice that just a block away from the factory is a rail line that almost exactly follows

the contours of the design that came to be the Delta Series.

Dave pointed out to us that some of the chassis

designs showed the original Classé logo, while others featured variants then being

considered for the Delta Series. "We had six logo designs submitted to us. The

Classé logo we now use was the first one we rejected." Dave went on to say that

"The first thing I thought when I saw the logo is that a customer would think that a

piece of silkscreen had chipped off the top left corner of the ‘E.’" Of

course the "missing" piece actually stood in for the accent aigu that sits atop the "E," but people unfamiliar

with French grammar might not get the subtlety. So how did the "chipped

silkscreen" look make a comeback? "At the same time we were considering logos,

we hired a marketing specialist to come here and provide advice on some sales materials. I

e-mailed him all six logo designs and told him to use whichever one he liked on the sample

materials he was bringing."

A few weeks later, when the marketer began his

presentation, the Classé team was surprised to see that the sample materials featured the

logo they’d rejected. Dave told us that he stopped the presentation and asked the

expert why he’d chosen that particular logo. "Because," he told his

audience, "this logo does something that most aspire to do but few ever achieve:

It’s memorable. If you see it a second time, you’ll remember that you’ve

seen it before." And with that, the "chipped silkscreen" logo, along with

the flowing lines of the Delta chassis, became the symbols of the new Classé.

Of course, another unmistakably Classé symbol is

the touch-screen panel that adorns the front of each of the company’s Delta products.

When the touch panel was first suggested for the Delta Series, there was some concern that

such technology would be too expensive to integrate into Classé’s products. But

since the company was going for bold reinvention, Dave Nauber decided that they might as

well go all the way, and the touch screen was in.

A touch-screen-equipped CP-700 preamplifier goes

through final testing.

After a lunch of Montreal smoked-meat sandwiches

(what else?), our factory tour began in earnest. Before we were allowed on the assembly

floor, Doug and I had to don static-free lab coats and shoe straps that connected us to

the factory’s electrically grounded floor. Properly equipped, we were led by George

Ujhegyi, Classé’s manufacturing engineering manager, with Dave Nauber acting as

color commentator to George’s play-by-play description of the factory.

The main assembly area of Classé Audio's spacious

factory.

Our first stop was Engineering Support, where

prototyping work is done and where circuit boards are designed from blank sheets -- or

rather blank computer screens. Classé’s circuit boards aren’t laid out using

so-called auto-routing software because those don’t take signal-path purity into

account and simply find the most expeditious way from A to B. At Classé, each individual

copper trace is laid out by a technician on a computer and is tracked through its entire

length to ensure that sensitive signal paths do not come too close to power feeds. The

coolest tool we saw in engineering support was a thermal-imaging camera, which is used to

obtain a precise heat map of Classé components. The idea here is to catch any heat build

up in components during the prototyping phase so that any issues are rectified before a

product moves toward production. This, of course, is a great benefit for component

longevity.

Next, we proceeded to the extensive

quality-control (QC) area. It can be said without any reservation that Classé takes

quality control extremely seriously. Take, for example, the aforementioned

electrically grounded factory floor. This exists to protect delicate integrated circuits

(ICs) from static-electricity discharges. Dave Nauber explained that before they are

installed, ICs can be damaged by environmental stress. For example, even plastic ICs, he

said, can be susceptible to moisture damage. Therefore, Dave insists on a very tight

"chain of custody" for all the parts used in Classé products. The company only

does business with suppliers and shippers who follow proper handling and storage

procedures.

Based on what we saw in the QC area, it seems

unlikely that a faulty part will ever make it out of the Classé factory, unless it’s

in the garbage. During our visit the QC team was inspecting amplifier and control circuit

boards for the B&W Zeppelin iPod dock. Two technicians, properly grounded with wrist

straps, were inspecting each circuit board under magnifying lenses and bright lights,

looking for improperly installed parts and cleaning the boards. Once they passed visual

inspection, each board was mounted to a custom electrical jig and subjected to a battery

of tests by expensive electronic testing gear. If they make it past this phase, the boards

are packaged up and sent to B&W.

Inspecting Zeppelin circuit boards.

Of course, the QC procedures are just as

stringent for Classé-branded products. An interesting feature of the company’s QC

process is its use of bar codes on every single individual circuit board that makes up a

product. At each step of the QC process the bar code is scanned; this records not just the

date and time, but a complete history of the board and the parts used on it. If a board or

component fails anywhere along the assembly chain, its entire history can be called up and

a postmortem undertaken to understand where the failure occurred, and why. The bar codes

also prevent a board from skipping a step in the QC process. If, for example, step B has

been missed and a board somehow shows up at step C, the computer won’t allow work to

continue until the B test is finished. I asked George how long Classé keeps the QC

history for each of its products. His answer: They still have that information for the

first Classé amplifiers produced in 1981!

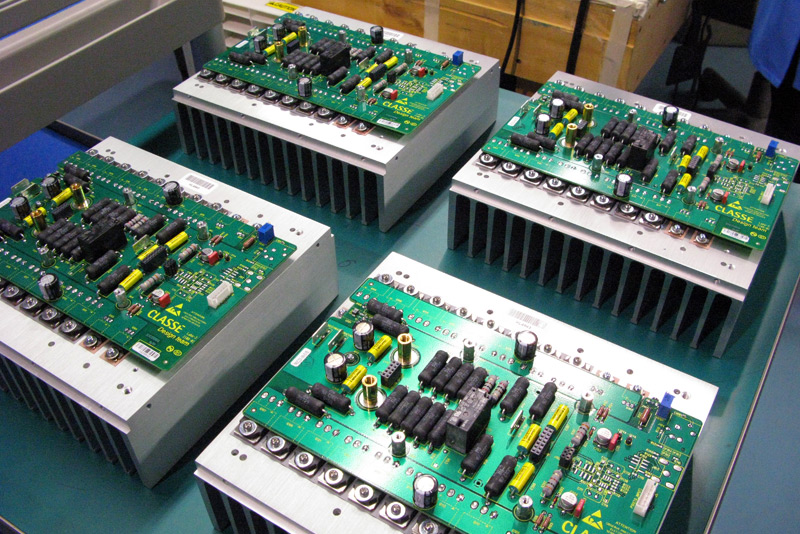

In the assembly area we saw quite a number of

amplifier output modules, destined for CA-M400 mono power amps, arrayed on a test rack.

Each amplifier board is run in at the factory for a minimum of 72 hours before it is

installed in a chassis. According to George Ujhegyi, this not only burns in the output

module (and its 16(!) output transistors), but it also allows the assembly technician to

bias the amplifier at full operating temperature, thereby ensuring that each amp is set up

properly. Awaiting these modules were a number of big CA-M400 chassis. Taking a look

inside one, I was amazed to see massive gold-plated copper bus bars that connect the

speaker binding posts to the output modules. The bars are so big that they’re bolted

to the binding posts, soldering not being an option on something so thick! Without

exaggeration, the things look like they could handle a lightning strike.

Output modules awaiting testing.

Our visit to the factory came just a few weeks

before the official launch of Classé’s new flagship SSP-800 preamp/processor.

I’m sure that the many customers who pre-ordered the $8000 device would be a little

envious to know that we saw dozens of these beauties lined up on shelves awaiting

packaging and shipment to their new homes. From what we saw of the SSP-800, it certainly

appears to be worth the wait. Look for a review of this new processor on a Soundstage!

Network website.

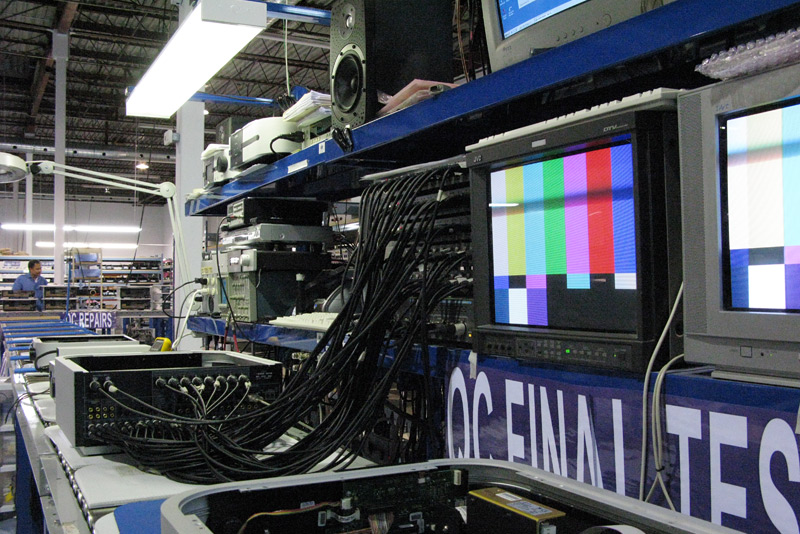

Speaking of the SSP-800, we also witnessed some

of these in front of a bank of equipment that might make NASA jealous, going through the

final QC test phase. Impressively, Classé tests every single input and output on every

one its components before the products are passed on to the shipping department.

Every input and output gets tested!

Believe it or not, the factory’s packaging

area was absolutely fascinating, because even Classé’s shipping cartons are products

of careful planning and attention to detail. The dense foam used to protect the precious

component is actually configurable, so that one size can be used for larger or smaller

components. The outer box is made from cardboard-like plastic and features handholds on

either end (other manufacturers, please take note!). The box lid also forms the sides of

the shipping container, so when it’s lifted off the base, the customer has easy,

360-degree access to the component because there are no side walls in the way. Anyone

who’s ever lifted a heavy amp out of a box would no doubt appreciate such

well-designed packaging. For reviewers, the Classé box is a dream come true. All of the

packaging is fully recyclable, but I can’t imagine why you’d want to throw away

such a nice box.

There's certainly pride in the packaging at Classé

Audio. That's George Ujhegyi on the left, David Nauber on the right.

Interestingly, even at this final stage of the

manufacturing process, the Classé barcode system shows its value. Here the codes are used

to ensure that the proper manual, power cable and remote control go into each box. Only

when the QC computer is satisfied that all is well does it authorize sealing up the box.

Though the shipping department may be the last

stop for Classé components, we still had one more department to visit. Often the most

interesting place in an audio factory is the research-and-development area, and this was

certainly the case here. Although we were sworn to secrecy, we can share a couple of

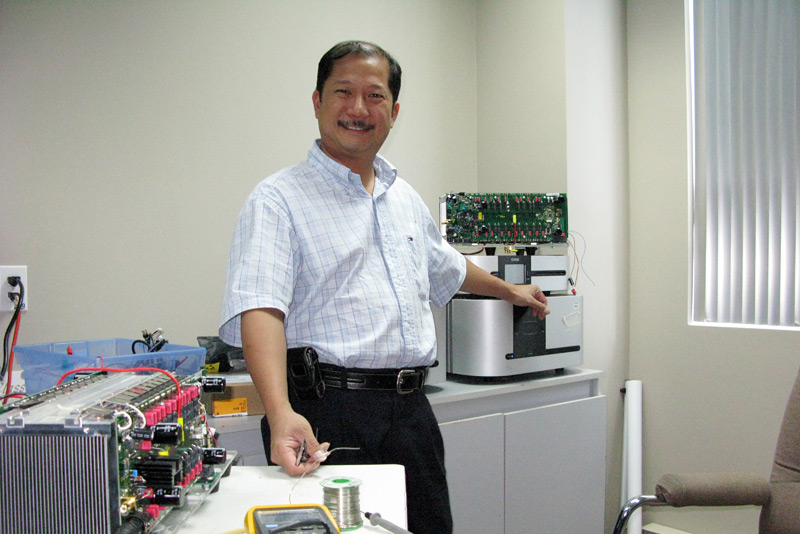

tidbits of information. First, Classé’s chief analog engineer, Nang Nguyen, proudly

displayed for us the distortion measurement of a new amplifier output stage he’s

working on. At a steady 100 watts of output power, the test gear reported an incredibly

low 0.0005% total harmonic distortion. That’s one more zero than you typically see

with an amplifier, or any other component for that matter. We can also report that Classé

is undertaking some beyond-the-cutting-edge work on power supplies. If all goes well, the

competition may soon find itself playing catch up.

Chief analog engineer Nang Nguyen.

Classé Audio’s success obviously

hasn’t happened by accident. Through careful planning, exquisite attention to detail,

and a dedicated and motivated workforce, Classé’s products have achieved critical

acclaim and a loyal following. Now that it has the resources of B&W behind it, and

with exciting new products entering production or going through development, it seems

certain that Classé will continue to push audio’s cutting edge ever forward. For the

"new" Classé Audio, it’s abundantly clear that the Delta Series is only

the beginning.

...Colin Smith

colins@soundstage.com

|